The development of electronic or digital printing systems and products has been the primary focus of mechanical engineering activity at XACTIV. Our specialized mechanical engineering expertise includes industrial design and human factors (IDHF), mechanisms, DFA/DFM, plastic and sheet metal, paper handling, media handling, fusing systems, optics, electrostatic powder deposition, fluid deposition, materials and surface technologies, mechanical analysis, and MEMS systems. From these core capabilities mechanical development at XACTIV has evolved to serve the widely varying needs of our clients.

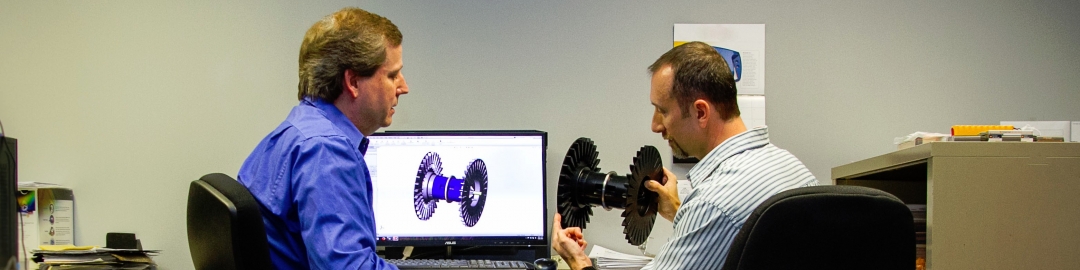

From a historical basis, as world-recognized experts in the many technologies of digital printing and materials handling, XACTIV’s technical resources have advanced to a high level of versatility. We use Solidworks® solid modeling software, including its FEA and PDM Workgroup extensions, and add a broad range of additional application expertise. XACTIV’s mechanical development activities consistently employ the latest rapid prototyping technologies and are recognized for their ability to provide rapid time to market advantage to our clients.

XACTIV’s engineers provide highly competitive mechanical designs for components, sub-systems, and complete instruments and manufacturing systems. Our team can be tailored to meet your needs, from the development of one simple gage to the design of the most advanced of mechanisms, instruments and machines. Additionally, the XACTIV mechanical development team is expert with the integration of state-of-art electronics and firmware. XACTIV’s interdisciplinary work environment allows its mechanical engineers to consult with materials, electronics, chemical and fluid science experts as well as electrical engineers and software engineers in architecting and designing the mechanical infrastructure of the most sophisticated office and consumer electronic or medical instruments.